- Wire Mesh[44]

- Cutting and Forming Tools[68]

- Personal Watercraft[3]

- Mining Machinery[1]

- Mazut[1]

- Cleaning Equipment[10]

- Food Processing Machinery Parts[2]

- Wiring Ducts[2]

- Dairy Processing Machinery[10]

- Snack Machinery[5]

- Other Food Processing Machinery[5]

- Beverage Processing Machinery[10]

- Fruit & Vegetable Processing Machinery[6]

- Conveyors[2]

- Food Sterilizer[1]

- Pasteurizer[2]

- Heat Exchanger[1]

- Contact Person : Ms. JI Judy

- Company Name : Shanghai Beyond Light Industry Machinery Co., Ltd.

- Tel : 0086-021-57175189

- Fax : 0086-021-57172728

- Address : Shanghai,fengxian,NO.4476 Hangtang Highway Fengxian Shanghai

- Country/Region : China

- Zip : 201411

hot filling processing machine

Description of tea beverage processing machine

this tea beverage production line produce several types of tea beverage, i.e. black tea, green tea, Herbal tea and so on.

This tea beverage production line raw milk can be tea leaves or tea powder or tea concentrate, sugar, stabilizer and flavors etc. the procedure method can be blending-UHT sterilizer-homogenizer-hot filling- cooling tunnel- pacakge and so on.

End product package of this tea beverage production line can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box, pre-pak pouches , Tetra pak etc. for this fruit juice production line according to different end product and package type, the production technology is differently designed, but commonly include the following steps:

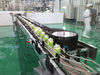

Photo show of tea beverage equipment

tea leave extracting system

UHT sterilizer

| equipment list for 6T/H tea beverage processing line | |||

| Flow No. | Name | Size | Technicals |

| A | Hot water unit | ||

| A-1 | hot water tank | V=6000L | SUS304 stainless steel, PU insulation, cone cover, sealed manhole, digital show thermometer, air vent, overflow pipe, anti-eddy plate, adjustable legs, thickness of tank wall is 3mm, outer 2mm, glas tube level indicator |

| A-2 | hot water pump | Q=10T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, water cool type doube seals; Inner Shell Bright-Polished |

| A-3 | plate heater | Q=10T/h | the supporter and frame is made of SUS304 stainless steel,PHE is SUS304, one heat section, hasp type seal rubber mat,heated by steam, pressure withstand 8kg |

| A-4 | steam regulation and temperature control system | UK spirax sarco pressure reduction valve,steam regulating valve,trap,Germany temperature sensor, pneumatic two position and three way valve, temperature auto-control system | |

| A-5 | hot water recycle temperature control system | GEAwater regulating valve,GEA pneumatic butterfly valve,Schneider or DELIXI electric components, temperature control meter | |

| B | tea leaves extracting unit | ||

| B-1 | extracting tank | V=1500L | SUS304 stainless steel material, PU insulation, central standing type agitator, sealed manhole, high and low level sensor, temperature sensor, residue and liquid discharge from bottom, ellipse cover head,cone bottom >45 degree, residue discharge outlet with pneumatic switch. |

| B-2 | centrifugal pump | Q=10T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| B-3 | screw conveyer for extracted tea residue | Q=1T/h | infinitive speed, 5 meters as one set |

| B-4 | vibration round sieve | Q=10T/h | SUS304, with 100mesh filter net, round sieve, and 200L temperary tank |

| B-5 | centrifugal pump | Q=10T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| B-6 | plate cooler | Q=10T/h | plate SUS304, two exchange sections, hasp type seal rubber cushion, heat exchange area is 14+10m2 |

| C | tea liquid filter unit | ||

| C-1 | tea liquid storage tank | V=3000L | SUS304 stainless steel, pu insulated, with agitator 960rpm at side, sealed manhole, CIP spraying ball, cone cover, adjustable legs, breath valve, sample valve, anti-vortex plate, digital show thermometer, high/low level transmitter |

| C-2 | centrifugal pump | Q=5T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| C-3 | disc type centrifuge | Q=5T/h | |

| C-4 | tea liquid storage tank | V=3000L | SUS304 stainless steel, pu insulated, with agitator 960rpm at side, sealed manhole, CIP spraying ball, cone cover, adjustable legs, breath valve, sample valve, anti-vortex plate, digital show thermometer, high/low level transmitter |

| C-5 | centrifugal pump | Q=10T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| D | syrup prepare unit | ||

| D-1 | high speed mixer | V=1500L | SUS304,heat insulation, high speed mixer at bottom of tank, PU insulated, digital show thermometer, anti-vortex plate, adjustable legs, high/low level transmitter |

| D-2 | centrifugal pump | Q=5T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| D-3 | duplex filter | Q=5T/h | SUS304,100M |

| D-4 | round disc type diatomite filter | Q=5T/h | filtration pressure is 0.6Mpa, include diatomite pre-painting tank, full-auto control |

| D-5 | plate cooler | Q=5T/h | plate SUS304, two exchange sections, hasp type seal rubber cushion, heat exchange area is 7+5m2 |

| E | blending system | ||

| E-1 | blending tank | V=6000L | SUS304 stainless steel,single layer,top off- center votical agitator 36rpm,conical head,airtight manhole, breather valve,digital readout thermometer,anti-eddy baffle,supporters with adjustable feet, glass tube level indicator |

| E-2 | centrifugal pump | Q=5T/h | SUS304 stainless steel,pump lift 24M,Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| E-3 | precision filter | Q=5T/h | SUS304,1U |

| F | homogenizer and sterilization and filling unit | ||

| F-1 | tubular sterilizer | Q=6T/h | hot filling, full-auto control, tubular 120°C,15s |

| F-2 | filling unit | Q=6T/h | |

| F-3 | turning over sterilizer | SUS304 stainless steel,polyformaldehyde plastic, conveyer chain made of SUS304 stainless, total length 12m,1.1kw frequency controled motor | |

| F-4 | spray cooling tunnel | main frame is SUS304, food grade chain, geared motor, speed adjustable, high pressure water pump, diamension L*W=14500*2250,include control box, water pipes etc. | |

| F-5 | afterward package | include drier,labler,label shrinking,coding,package | |

| G | CIP system | ||

| (G-1~6) | full auto-CIP system | 4×1000L | SUS304 stainless steel, full-auto control,single cleaning way,Germany temperature control system, USA concentrated acid/alcali adding system,100L×2 SUS316l tanks for concentrated acid/alcali |

| G-R | CIP return pump | Q=20T/h | SUS304 stainless steel,pump lift 24M,suck head 4m, Hard Alloy Mechanical Seal,Inner Shell Bright-Polished |

| H | stainless steel operation plateform | ||

| H-1 | operation platform for material feeding | SUS304,1.5Χ1.5Χ1.2 | |

| H-1 | operation platform for prepare unit | SUS304,6Χ1Χ1.8 | |

| I | installation | include stainless steel and carbon steel pipes and fittings etc | |

hot filling processing machine